At Hines we have a strong emphasis on teamwork, quality, and customer satisfaction. Our employees have diverse talents and experiences. We also have opportunities for students to develop hands-on experience working with some of the best engineers in the industry.

We are actively searching for candidates for the following openings:

Interested persons may send their resume and cover letter to:

Attn: Human Resources

Hines Industries

240 Metty Drive

Ann Arbor, MI 48103-9498

This email address is being protected from spambots. You need JavaScript enabled to view it.

Duties

Human Resource Responsibilities

Requirements

Interested persons may send their resume and cover letter to:

Attn: Human Resources:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Hines Industries next Balancing Theory Seminar will take place on September 24, 2025. This 4 hour course includes engaging virtual classroom training. Our trainers have over 70 years of experience in the balancing industry combined. With training, attendees will improve their balancing processes, identify unbalance, correct unbalance, understand the goals of different kinds of tooling, and reduce errors to save time and money.

FIRST (For Inspiration and Recognition of Science and Technology) is a nonprofit organization with robotic programs for students aged 4-18. The programs are designed to inspire the next generation to purse career opportunities in STEM (science, technology, engineering, and mathematics).

This year, Hines will sponsor the TechnoDogs robotics team from Brighton, MI. The Brighton High School team competes in the FIRST Robotics competitions at state and international competitions. Community leaders contribute as mentors and sponsors at the tournaments to help students build a network of business and engineering professionals that help foster their skills. Jacob Jackson from Hines engineering team, has volunteered as a coach to assist students with engineering and CAD.

We wish the team luck on future competitions!

Computer hardware and software are changing rapidly. Hines Industries is now offering another computer upgrade option for your existing HVR, HO or HC manual balancing machines. This affordable option has been created for shops with lower volumes who still want to ensure repeatability, accuracy and precision.

Please note this computer is not compatible on semi-automated or fully-automated balancing equipment. It is available for the Hines Aftermarket HC500 machine without scale or bobweight integration. Contact our service department to discuss computer upgrade options.

Hines Industries is known for our “Legend series” crankshaft balancing machine dedicated to racing, high performance and aftermarket rebuild automotive sectors. For high production crankshaft needs, Hines has engineered and manufactured a new line of crankshaft balancing machines geared towards industrial manufacturers. The new Hines Industries Model HC line includes a range of models for crankshafts weighing 20lbs up to 5000 lbs.

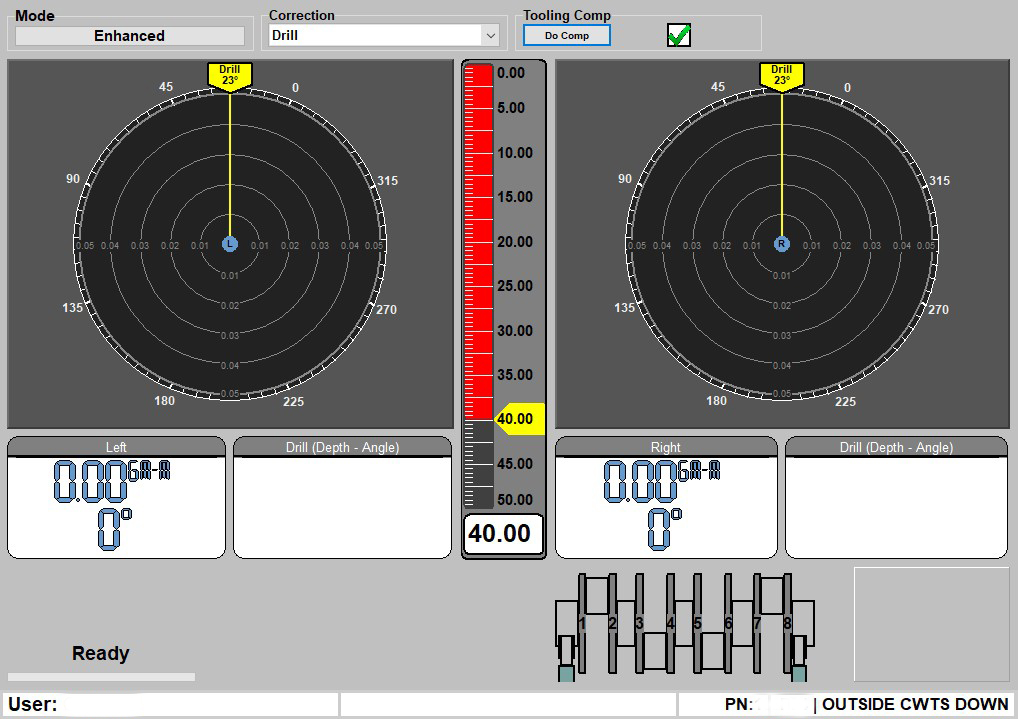

The balancing process is simple. An operator loads the part onto the machine and scans the crankshaft serial number. Once the guard door is closed, the crankshaft spins and unbalance is measured. The computer displays precise location where corrections is needed. The operator moves the drill press to the recommended correction position to enable the drill press. If the position is not lined up correctly, the drill press will not start. This eliminates the chance of operator correction location error. Once in the correct position, the operator drills the crankshaft utilizing the digital drill depth display on the computer. The machine read-out verifies that the drill press has gone to the recommended correction hole depth and indicates the correction hole has been complete. A chip vacuum automatically collects debris left from drilling.

Once all corrections have been made, the operator closes the door and initiates the spin cycle. If the balance specifications are met, the machine stamps a mark to indicate it has passed the balance specs. The crankshaft is removed and the balancing data is saved on the computer. At the end of the day, operators are able to see a full report on number of parts run, number of parts that passed specs, along with initial balance and final balance data.

This latest design reduces operator errors, improves accuracy, and ensures balancing processes are completed effectively. It also saves time by taking the guess work out of balancing. This is only one example of the many configurations and weight ranges available. For standard or custom balancing solutions, Hines engineering and manufacturing expertise can assist you with a balancing equipment package to meet your requirements.

Hines Industries, a Michigan based manufacturer, has engineered and manufactured its first balancing machine specially designed to balance autonomous sensors on self-driving vehicles. A well-balanced sensor will increase the sensors efficiency, when factors such as longevity, safety, and noise play an important role for lidar manufacturers, through reducing the vibration caused by imbalance.

Not all parts within a lidar need to be balanced, only the components that rotate. This poses a unique challenge when designing a balancing machine to incorporate a motorized lidar assembly. Hines engineers redesigned the Hines model HVR to accommodate the spinning sensor without a balancers spindle.

The Hines Industries custom model HVR-50 is a computer based, two plane, manual load, single station balancing machine. The balance mechanism uses a rugged hard suspension HVR (vertical axis, rotating) system to support the weight of the workpiece. Unlike most Hines HVR machines, this machine has no spindle and instead is driven by the motorized lidar assembly.

Hines programmers created a custom balancing program to incorporate the customers part and motor drive into the balancing machine software. Unbalance is identified and displayed on the computer screen allowing a machine operator to make a correction. After a part has been balanced below its tolerance, “Good Part” is displayed on the computer screen.

With Hines proven technology, the company is able to use their expertise for other lidar manufacturers looking for a balancing solution that is unique to their sensor needs.The Hines team has produced an entire line of balancing equipment that includes manual, semi-automatic, and fully automatic systems for a wide variety of tolerances and manufacturing throughput requirements.

Hines Industries will continue to serve our customers who are essential in the medical industry.

Rotating components such as turbines, blowers, fans, motor assemblies and motor armatures in ventilators, respirators and other medical supply equipment need to balanced. Hines has designated a team to build small balancing machines in order to assure timely delivery for our medical customers.

For customers who require a rapid response to balancing needs, Hines is here to help. Our fully equipped balancing service includes dynamic and static balancing on horizontal and vertical balancing machines.

Shown above is a recently built HC .5 that can be used to balance motor fan/turbine assemblies and their components.

To our valued Customers and Suppliers:

The State of Michigan has issued an order to “Stay at home”, and other states and localities are implementing “lock down,” "stay at home," or "shelter in place" orders for citizens and temporary closures of "non-essential" businesses and services to combat the spread of Coronavirus Disease 2019 (COVID-19).

Hines Industries is an essential supplier to customers in the Defense Industrial Base Sector, Medical Sector, Food & Agriculture Sector and Transportation Systems Sector. These sectors have been identified by the Department of Homeland Security as Critical Infrastructure Sectors. Therefore, Hines will keep its doors open to serve our customers who are essential to national security and defense, and/or the transportation, medical or food supply chains.

Hines Industries will:

1. Provide customer service and field service to our customers, and

2. Designate employees to report to work in order to assure timely delivery of machines and spare parts to our customers.

Hines Industries is also taking the following measures:

▪ Screening Questionnaire. Employees necessary to provide critical, time sensitive repairs at customer locations are required to complete a screening questionnaire.

▪ Social Distancing. Employees reporting to work must practice social distancing, which means taking steps to maintain a distance of six feet from others when possible.

Please feel free to contact us directly for any questions related to our continuing operations and travel by our Service Technicians to customer plants.

To save this letter, please click here

The Hines Industries Model HC-5000 balancing machine is a computer based, dynamic (two plane), or static (single plane) manual load, single station, balancing machine configured for balancing crankshafts weighing up to 5000 lb. A drill will be mounted on a slide for in-place correction of unbalance. The drill is adjustable to set up a range of part dimensions and is manually fed in operation.

An Industrial PC utilizing the Windows operating system, with a flat panel touch screen. Additional features provided with the computer include:

• User-friendly on-screen menu system for quick and easy operator use

• High-resolution, flat panel, touch screen displays large characters

• Unbalance amount is displayed in digital and vector-graphic simultaneously

• Display of unbalance AMOUNT and ANGLE, and TOLERANCE

• Special Multi-plane correction calculations

A plant tour will be given showing the many departments that work together to produce a Hines balancing machine. These departments include electrical engineering, mechanical engineering, controls engineering, assembly, painting, machining, sales, marketing, service, purchasing, accounting, scheduling and shipping.

Hines department heads will discuss their role in designing and manufacturing a balancing machine to showcase the many career opportunities available in a manufacturing environment.

Attendees will use a hand held balancing tool simulator and discover the different types of unbalance.

Depending on machine floor availability, attendees will be able to see a manual, semi-automatic and fully automated balancing machine in operation.

FIRST (For Inspiration and Recognition of Science and Technology) gives students of all ages a chance to work alongside adult coaches to discover and solve a scientific problem. This year’s theme was Mission Moon where students built a moon base consisting of basic resources such as air, water, oxygen, food, etc. Students used LEGOS to build and program a robot. FIRST Lego League JR World Festival Expo will take place in Detroit from April 24-27, 2019 where students will present their ideas with a poster and presentation.

Rimpi (shown above) is an Electrical Engineer at Hines Industries who volunteers as a team coach for Abbot Asteroids II. Rimpi enjoys teaching the children team building and problem solving skills.

CEO, Dawn Hines (shown above) is a team coach for Abbot Asteroids I. Hines Industries is proud to sponsor and coach team Abbot Asteroids I and Abbot Asteroids II.

To maximize machine uptime, Hines Industries introduces new levels of service and support for existing customers. Our service level agreement plans allow you to budget for inspection, preventive maintenance and repairs in advance to ensure longevity, repeatability, accuracy and precision for your manufactured quality parts. Hines offers three different levels of coverage (Silver, Gold and Platinum) to ensure all customers can benefit.

The Michigan Hyperloop team will compete at the 2018 Hyperloop Pod Competition on July 22, 2018. All pods must be self propelled and the competition will be judged on speed. Hines Industries is proud to sponsor the Michigan Hyperloop team by providing balancing services. The force created by unbalance increases exponentially with speed. Balanced wheels reduce vibration, reduce damage at high speeds, and reduce significant damage to bearings/suspension. For more information on the University of Michigans Hyperloop team, click here.

Not Finding what you're looking for? Let us help. Click here or Call (734) 769-2300.