Hines manufactures dynamic balancing machines for anode x-ray tube rotors. Whether you need a balancer for a manual operation or you are producing parts at a production level and need automatic balancing equipment for your anode x-ray tube, Hines has a balancing machine model to fit.

Automatic Anode X-ray Tube Balancing Machine

Automatic Anode X-ray Tube Balancing Machine

Hines has engineered and manufactured semi-automatic balancing machines for production level balancing. This type of machine automatically corrects by drilling in each plane, with both radial and axial drilling. All Hines balancing machines are hard bearing which means they are permanently calibrated and rugged enough for on-machine drilling correction.

Features include:

- Two plane (dynamic), hard suspension balancing

- Transfer: Fully Automatic

- Correction: Drills correct both planes with axial and radial drilling. Encoded servo feed assures precise drill depth.

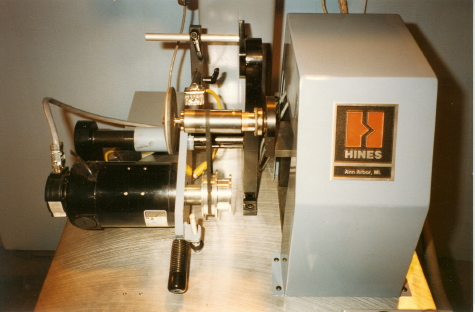

Manual Anode X-ray Tube Balancing Machine

Manual Anode X-ray Tube Balancing Machine

Hines Industries Model HO-20 balancing machine can be configured and tooled for balancing anode x-ray tubes.

Features include:

- Two plane (dynamic), 20 lb. capacity hard suspension balancing

- Transfer: Manual load and unload

- Correction: The part is marked for correction after unbalance is measured. A drill mounted on a separate base is used for part correction

- Special Software: The Number of Holes software informs the operator of the depth and location of the holes required for correction.

Manual Balancing Operation

The operator places the anode x-ray tube rotor in the balancing machine. The machine spins the part and displays the amount of correction required to balance the rotor. The balancer will tell the operator how much material to remove from the rotor and at what angle. Based on the specifications for each stored part number the balancer will display the amount to remove for each size of anode x-ray tube rotor.