The right balancing machine for your pump impeller components depends on your specific balancing requirements. Your particular application may require single plane or two plane correction, and on or off machine correction, and a manual, semi-automatic, or fully automated balancing process.

The photo on the top-right shows a Hines HO-100, a single station, horizontal overhung balancing machine configured and tooled for balancing pump impellers. Click here for more information about the HO.

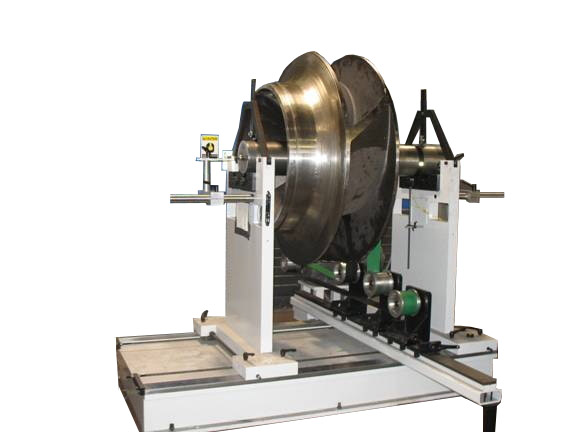

On the right in the middle is a Hines HC-1000, a single station, horizontal cradle balancing machine configured and tooled for balancing pump impellers. Click here for more information about the HC.

The photo on the lower-right shows a vertical rotating (HVR) impeller balancing machine with off machine correction. Scroll down to see a semi-automatic HVR-100 with automatic belt grinding correction. Click here for more information about the HVR.

And below the features list is a photo of a semi-automatic HVR impeller balancing machine configured and tooled for parts up to 100 pounds. Call Hines to discuss your tolerances and to request a specification and quote.

Balancing Instrumentation:

- Customized level of automation

- Easy-to-use touchscreen control

- Precision tooling for short and long bore impellers

- Blended correction for a more efficient impeller

Balancing Features:

- Automatically zeroes out tooling unbalance and eccentricity

- Software accounts for keys and keyways

- Balance tolerance based on the part weight and usage RPM

- Unbalance vectored into two segments

Benefits of Impeller Balancing:

- Reduced labor time per part

- Reduced warranty costs

- Reduced operator fatigue

- Reduced potential for work-related injuries

Click here to read articles related to Pump Balancing

Automatic Belt Grinding