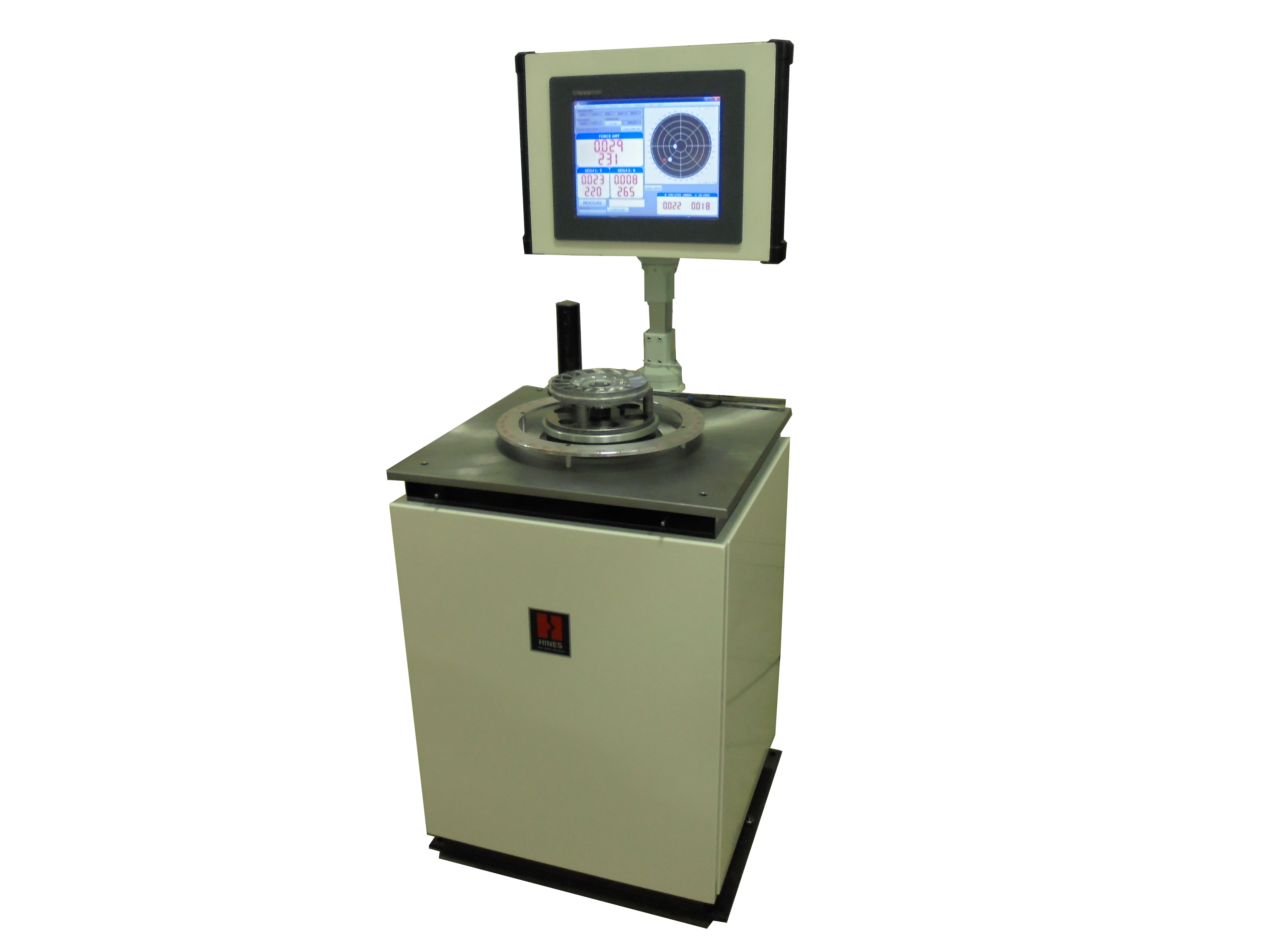

Hines offers leading edge vertical, horizontal, static (non-rotating), and dynamic (rotating) machines. Whether you have a standard rotor that can be balanced with single-plane correction or a part that requires two-plane balancing with segmentation, we can find the best solution for your balancing machine requirements. We can work with individual parts, components, or systems of components.

Hines offers leading edge vertical, horizontal, static (non-rotating), and dynamic (rotating) machines. Whether you have a standard rotor that can be balanced with single-plane correction or a part that requires two-plane balancing with segmentation, we can find the best solution for your balancing machine requirements. We can work with individual parts, components, or systems of components.

Hines offers more than 50 standard dynamic balancing machine models and hundreds of specialized balancing equipment configurations including robotics, conveyors,  and lasers. Hines balancing machines are capable of balancing more than 100 parts per hour while holding the tightest tolerances. Hines engineering and manufacturing expertise can assist you with a balancing equipment package to meet the most demanding balancing applications.

and lasers. Hines balancing machines are capable of balancing more than 100 parts per hour while holding the tightest tolerances. Hines engineering and manufacturing expertise can assist you with a balancing equipment package to meet the most demanding balancing applications.

The balancing machine model that is right for your application depends on the attributes (including size, weight, change of shape when rotating) and  variety of the parts that will be balanced, throughput requirements, and other details about your manufacturing process.

variety of the parts that will be balanced, throughput requirements, and other details about your manufacturing process.

Available Tolerances

- All Hines balancing machines measure and display force unbalance (where the amount of unbalance can be measured within 1 plane)

- All of the machines (except the non-rotating HVS),

will measure and display dynamic unbalance, two plane unbalance, and force unbalance. Force and couple unbalance are available upon request.

will measure and display dynamic unbalance, two plane unbalance, and force unbalance. Force and couple unbalance are available upon request. - Segmentation is a standard on all Hines machines. The unbalance is broken down, or vectored, to accommodate limited areas of correction. An example is a fan with five (5) blades, or another part with locations for correction which are limited and symmetrical.

Dynamic Balancing Applications

Vertical balancing machines (HVR) and (HVS) are typically used for balancing flat or plate shaped rotors

Vertical balancing machines (HVR) and (HVS) are typically used for balancing flat or plate shaped rotors- Horizontal Cradle (HC) balancing machines are also referred to as universal balancing machines for the wide variety of part shapes it can balance and the fact that it provides single or two plane balancing

- Horizontal balancing machines (HO) are used for single and two plane, dynamic balancing

- Driveshaft (DL) balancing machines are used for shaft type parts