Based on the mechanical design of the Hines Cradle balancer (HC), this computer has many special features and software for balancing crankshafts. It features a PC utilizing the Windows 10 operating system, with a flat panel touch screen. The software in conjunction with leading edge electronics provides a system that is fast, accurate and easy to use. Data Acquisition/IO/Encoder board as well as electronic filter board are enclosed within the computer case along with the PC components. These allow for precise electronic measurement of the unbalance. Part setup is quick with the menu based system. Setup options include measurements in either inches or centimeters, weights in either ounces or grams. Part setup and bobweight information can be printed and stored for future reference. Software includes many screens tailored to balancing crankshafts.

Software Features:

• User friendly menus allow for easy setup and easy operation

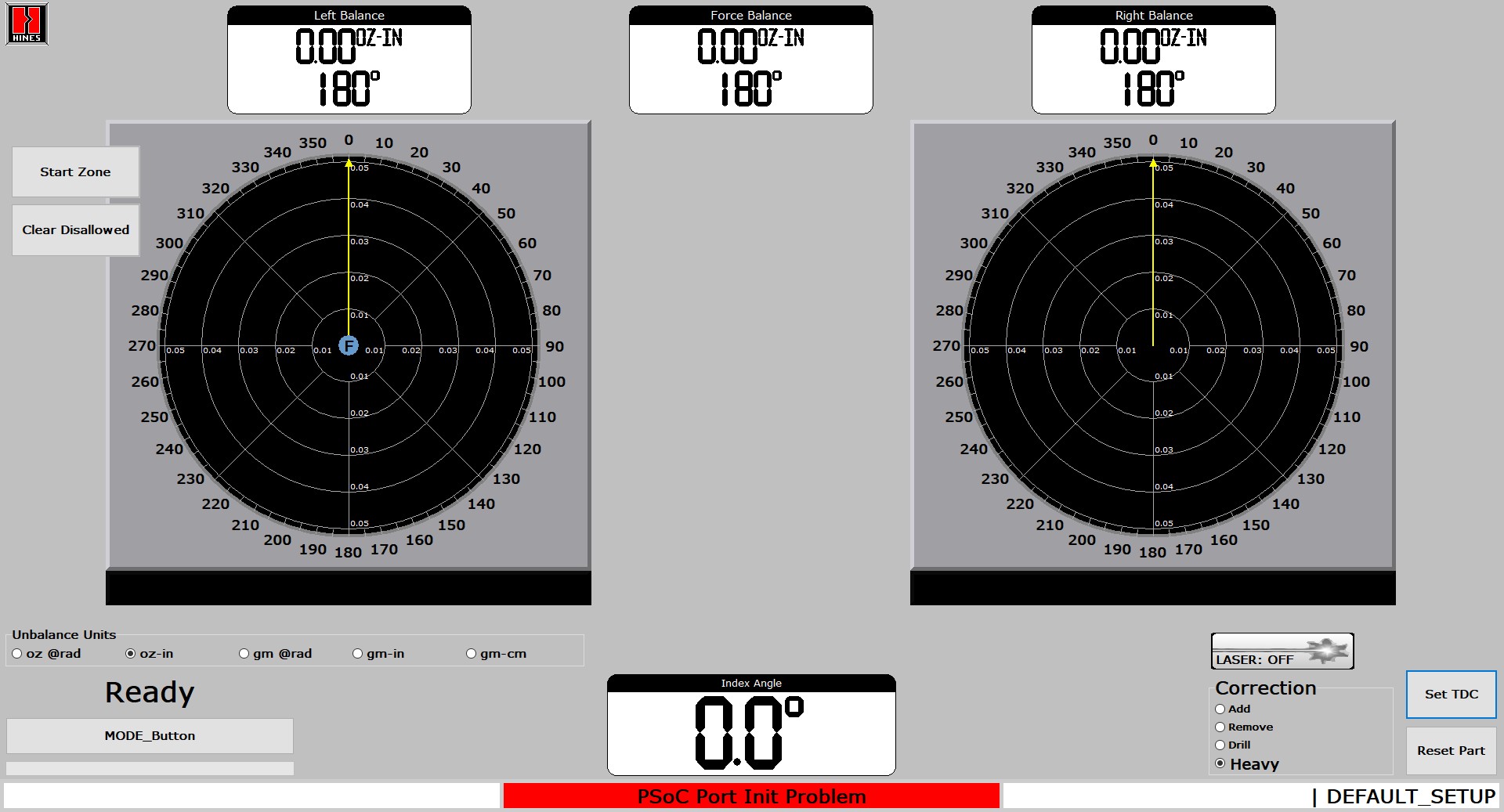

• Unbalance readout is displayed in both numerical format and as a polar graph

• Dual Polar Displays makes for easy interpretation of balance results

• Single or Two Plane balance readings (dependent on application)

• Balancer displays “Good Part” when balanced to specification. Specification based on adjustable tolerance in PC software

• Unlimited part setups and jobs storage

• Automatically calculated multi-hole drilling calculations tell you how many holes, where to drill, and how deep

• Automatically calculated heavy metal corrections allow you to make even larger corrections using Mallory metal. This may be necessary for jobs with more intense engine modifications

• Part Orientation Angle Indicator. Allows PC to display the angle that the part is rotated to in respect to the machine. Connects to the part via easily attachable magnet

• “Engine Build Sheet” software allows for entry of all details of your engine build

• Fan-less computer enclosure makes the computer well suited for dirty environment

Optional Software Features:

• Compu-match allows the computer on the balancing machine to communicate with the digital scale, walking the operator through all weight matching procedures. Information is automatically inserted into bobweight calculations.

• The graphic depth encoder eliminates the guess work when making on-machine corrections. The operator is provided a bar graph showing the amount of correction required. This feature is especially useful for less experienced operators.

• Laser alignment system helps you line up the part exactly where it needs to be drilled.

The standard PC specification includes:

• Windows 10®

• 240 GB Hard Drive

• 1 GB Memory

• CD-RW (Optional)

• 4 USB Ports (1 not committed)

• Keyboard

• Internal ethernet card 10/100/1000