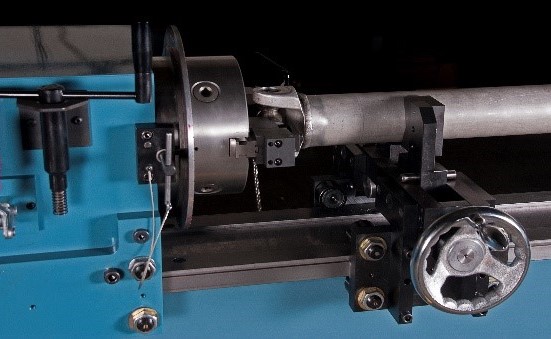

Hines P.S.W.S Machine

The Hines P.S.W.S. (Push up press, Straighten, Weld, Straighten) is designed to automate the building or rebuilding process of an automotive/truck/train/industrial driveshaft. Standard two jaw chucks which have been modified to accept a u-joint are included. The PSWS uses a 25-ton hydraulic ram that simultaneously pushes both ends of the shaft. This saves considerable labor time in assembling shaft components. Tooling holds the shaft centerline during the push up process eliminating excessive run-out. Unit includes a phasing locater pin, which ensures proper phasing of shaft ends. Tooling is also included to install carrier bearings. Adjustable holder for customer supplied weld gun is included.

Specification

Power 220 Single Phase

Shaft Max Length 100 in.

Max Tube Diameter 6 inches

Max Push-up Force 60,000 lbs.

The unit is equipped with a PLC controller and two non-contact run-out sensors. The controller is touch screen with full graphic display. Shaft run-out is determined and displayed based on one rotation of the shaft. It will then automatically index the shaft to the top dead center location for correction. After straightening, the weld mode can be set to weld seams at a programable RPM based on tube diameter and weld speed. The machine also has a programmable weld overlap feature. The PLC comes equipped with a part set up feature that can store and recall different shaft diameters.

See the PSWS in action