Straightening Machines

Straightening MachinesIn addition to balancing machines, Hines Industries manufactures computer controlled, straightening machines. A straightening machine can be used to automatically straighten your rotors to fine tolerances. Hines machines straighten: axles, gears, shafts, spindles, tooling, tubing, and turbines.

Straighteners can test for runout in one to five or more locations. Total Indicated Runout (TIR) can be measured by contact or non contact sensors on smooth to irregular or splined surfaces. Hines straighteners are known for their accuracy, repeatability, speed, and small floor space requirement. Runout (TIR) gaging may be added to any of our balancing machines as well.

Balancing Equipment Upgrades & Retrofits

Balancing Equipment Upgrades & RetrofitsUpgrade or refurbish your existing Hines balancing machine or retrofit a balancing machine from another balancing machine manufacturer. Machine Refurbishment will make any machine look and perform like new. Warranty is available.

Upgrade your existing balancing equipment with the latest computer and software packages. Click on the text links below for more information.

Hines offers manual, semi-automatic, and fully automatic solutions for moment weighing for connecting rod weighing, matching, and sorting balancing applications.

Drive Shaft Rebuild Press, Pushout

Drive Shaft Rebuild Press, PushoutThe Hines Push-Out Press is a fast and efficient way to remove end fittings from damaged shafts. Proper removal includes cutting the weld on the end fitting using the Hines lathe. Cutting the weld creates a lip that will allow the Hines Push-Out-Press to separate the fitting from the shaft. This machine can just as easily be used to remove center bearings.

Physical size: 60 in. long x 48 in. wide

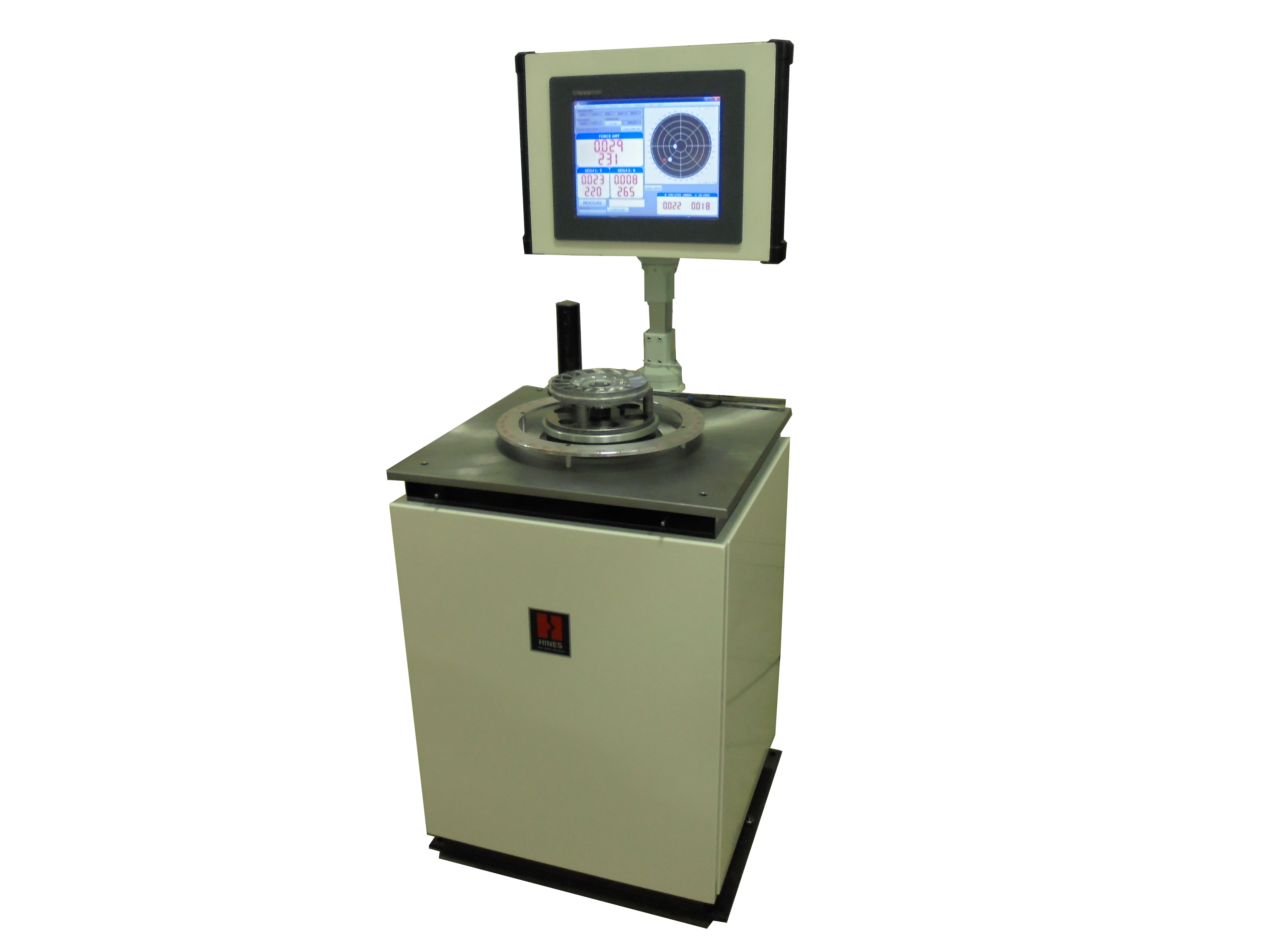

Non-Rotating Vertical Balancing Machine (HVS)

Non-Rotating Vertical Balancing Machine (HVS)The vertical, non-rotating or static balancer is used for single plane balancing where only force unbalance exists. Static balancing can be applied to grinding wheels, propellers, refinery plates, tires, and wheels. On this type of balancing equipment, the part is  suspended on its axis center on a frictionless pivot. The amount and direction of the tilt is precisely recorded by patented electronics and mechanical design. Spinning is not required allowing for fast, accurate, readings. This machine balances a wide variety of rotors including grinding wheels, disc brakes, refinery plates, fans, composite material propellers, clutches, pulleys, tires, and wheels to name a few.

suspended on its axis center on a frictionless pivot. The amount and direction of the tilt is precisely recorded by patented electronics and mechanical design. Spinning is not required allowing for fast, accurate, readings. This machine balances a wide variety of rotors including grinding wheels, disc brakes, refinery plates, fans, composite material propellers, clutches, pulleys, tires, and wheels to name a few.

Touchscreen Computer

Touchscreen ComputerNot Finding what you're looking for? Let us help. Click here or Call (734) 769-2300.